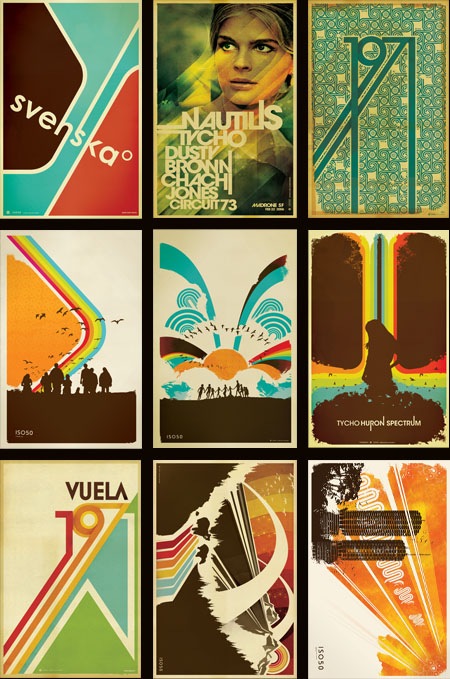

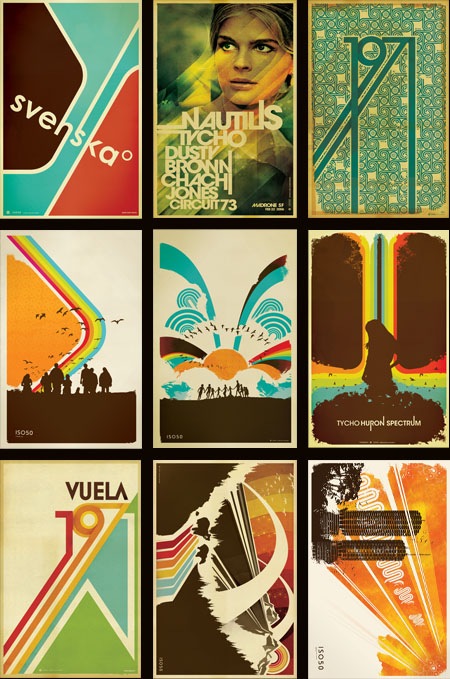

The prints you see above have all been reprinted and restocked over at The ISO50 Shop. Many were out for quite some time and they usually move fast once back on the shelves, so if you’ve been holding out for your favorites to be in stock, now’s the time.

I often get asked where I get my prints made so I thought now would be a good time to touch on that subject and go into a little more detail about the process. I have all of the small format posters done at a print shop in Sacramento, CA called Blue Moon Printing & Graphics. I found the place back when I used to live in Sacramento and even after moving to San Francisco I still use them as my primary printer. They are a relatively small shop so the service and attention to detail is far beyond anything you’ll find at some of the larger printing companies. I’ve found that personal attention to the output is the key element in getting your prints back looking the way you intended. It’s very difficult to make the transition from what you see on your screen to a printed piece of paper and no matter how well calibrated your equipment is you’re always going to experience a shift in color, saturation, contrast etc. The trick is to tweak the original file and the printer itself to try and compensate for these shifts and it’s important to find a print shop that is willing to work with you through this process.

I have the prints made on a digital thermal press which is essentially a toner-based process. I really like the output of this process because in the darker areas the toner builds up a thicker layer, giving an almost screen-printed effect when viewing an area of high contrast (such as a transition from cream to dark brown; the dark brown will appear to be painted on top of the cream background). The other advantage of the digital press (as opposed to offset) is that there are no plates involved so proofing and tweaking is a much quicker (and cheaper) process. You can adjust the file and run off a new proof in about 5 minutes as opposed to etching new plates and resetting the press as you would in an offset scenario. The only real downside of this process is the format limitation, the prints can only be 12"x18" at the largest. You are also limited to the type of paper you use as the toner won’t adhere to coarser papers; although I like to use a natural tone cover stock which is pretty smooth so this is not a big issue for me. The natural tone stock also has a yellow cast to it so that the yellow range in the lighter areas of the image is boosted. It gives the image a sort of aged, authentic feel which I think takes a bit of the edge off the digital output.

Blue Moon does have a traditional offset press but they just recently got it and I’ve yet to test it out. If you’re looking for a good printer I highly recommend them, and since they can do the whole proofing process via mail it doesn’t really matter where you’re located (my friend in New York does all his printing through them). You can find more information at their website: http://blumoonprinting.com.

I’ll be doing a post on monitor calibration soon in which I will go into more detail about preparing work to be printed and working with color profiles and printers…stay tuned.

![11_02[1]](https://blog.iso50.com/wp-content/uploads/2008/07/windowslivewriterpdp11handbook-1c7d11-021-thumb.jpg)

![11_03[1]](https://blog.iso50.com/wp-content/uploads/2008/07/windowslivewriterpdp11handbook-1c7d11-031-thumb.jpg)

Up top is the original handbook for the

Up top is the original handbook for the

![ib9[1]](https://blog.iso50.com/wp-content/uploads/2008/07/windowslivewriteribmslides1975-304dib91-thumb-1.jpg)

![ib23[1]](https://blog.iso50.com/wp-content/uploads/2008/07/windowslivewriteribmslides1975-304dib231-thumb-1.jpg)

![ib7[1]](https://blog.iso50.com/wp-content/uploads/2008/07/windowslivewriteribmslides1975-304dib71-thumb-1.jpg)